Esperence Nickel Sulphate Plant

Carlingup Sulphide Nickel Project

Nindilbillup Lateritic Nickel Project

Download Flyer

Esperance Nickel Sulphate Plant

Click <here> to download

Carlingup Sulphide Nickel Project

Background

Carlingup is a low grade nickel sulphide project located about 15km east of the town of Ravensthorpe in Western Australia. The key to successful exploitation of the deposits comprising Carlingup is to have a low capital and operating cost operation together with maximising payables on the end products.

Carlingup will be developed as a low cost open pit mining operation followed by heap bioleaching to leach nickel, copper and cobalt into solution. This solution will then be processed in a simple hydromet plant to produce an intermediate mixed hydroxide precipitate (MHP) in a slurry form to be trucked to Esperance for further processing into high value products.

The production rate at Carlingup will be set to ensure a steady feed of 2,230 tonnes per annum of contained nickel within the MHP which will in turn be processed into 10,000 tonnes per annum of high value nickel sulphate.

Alpha Fine Chemicals Limited (AFC) has successfully completed a Scoping Study on the development of Carlingup as a heap bioleaching operation to feed the Esperance Nickel Sulphate Plant. This study has confirmed robust economics for this development pathway.

Location

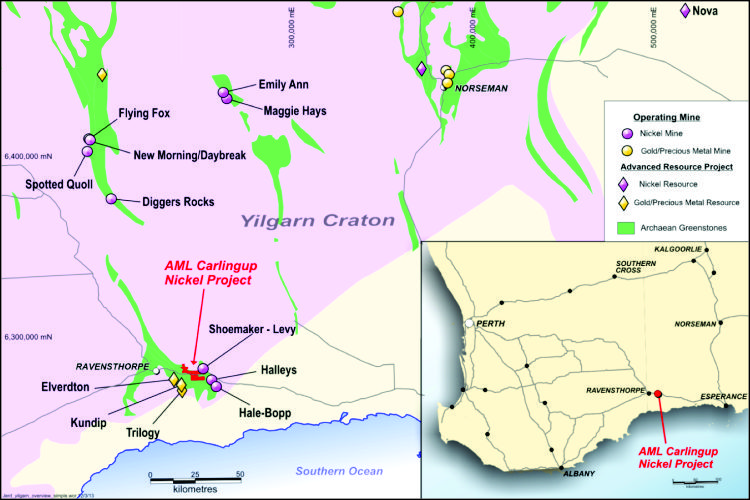

The Carlingup resources owned by AFC include RAV1, RAV4 and RAV4 West (RAV4W). They are situated in Western Australia, approximately 15km east of Ravenstorpe and 25km from First Quantum Minerals (FQM) Ravensthorpe Nickel Operation (RNO), as shown in the figure below.

Figure 1: Location and Regional Setting, Carlingup Project. Note that Alpha Fine Chemicals was previously called Australasian Mining Limited or AML.

Mineral Inventory

The RAV deposits which make up the Carlingup project were discovered by Pickands Mather International (PMI) in the late 1960’s. Neither PMI nor the subsequent project owners published a JORC resource for the deposits. AFC has now consolidated four decades of exploration work and had Golder Associates calculate a total mineral inventory which is summarised in the table below.

Summary of Carlingup Nickel Inventory

| Deposit | Tonnes (kt) | Ni (%) | Ni Metal (kt) | Co (%) | Cu (%) |

|---|---|---|---|---|---|

| Rav1 | 2,397 | 0.53 | 12.7 | 0.020 | 0.052 |

| Rav4 | 4,789 | 0.44 | 21.1 | 0.012 | 0.025 |

| Rav4 West | 3,200 | 0.42 | 13.4 | 0.019 | 0.058 |

| TOTAL | 10,386 | 0.46 | 47.2 | 0.016 | 0.041 |

The cobalt and copper grades will allow for the production of valuable co-products via the Esperance plant.

Production

The production rates at Carlingup are designed to ensure a steady feed to the Esperance nickel sulphate plant of 2,230 tonnes per annum of contained nickel which in turn allows that plant to produce 10,000 tonnes per annum of nickel sulphate. At this rate the production levels of the key metals from each deposit are expected to be:

| Deposit | Nickel (tpa) | Cobalt (tpa) | Copper (tpa) | Mine Life (years) |

|---|---|---|---|---|

| Rav1 | 2,230 | 77 | 142 | 3.25 |

| Rav4 | 2,230 | 58 | 84 | 5.25 |

| Rav4 West | 2,230 | 93 | 205 | 3.50 |